Virtucasa Classroom | Ancient Chinese Jade-Carving Tools

(Everything a curious undergraduate needs before touching a diamond blade)

Introduction – Why Iron Wheels Still Matter

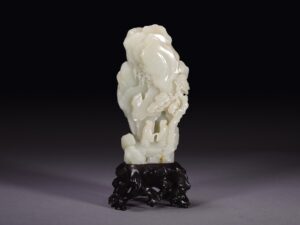

Modern CNC machines can rough-shape a jadeite bangle in minutes, yet master carvers in Suzhou still keep a worn iron 鋸陀 (jùtuó) on the shelf. The reason is simple: a 0.3 mm “traditional” blade wastes 40 % less material than the thinnest diamond rim. This article walks you through the entire historic toolkit(jade carving toolkit)—cutting, drilling, polishing—so you can understand both the physics and the poetry behind every stroke.

1.Cutting & Carving: The 陀 (tuó) Family

陀 is an umbrella term for any rotary blade or burr mounted on the horizontal spindle of a 水凳 (shuǐdèng, foot-powered lathe). Four subtypes dominate the archaeological record:

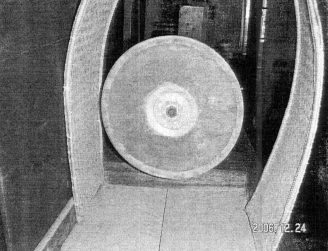

- 鋸陀 (jùtuó) – “guillotine” disc

– Ultra-thin wrought-iron disc, 80–200 mm Ø, 0.3–1 mm thick.

– Used for slab-slicing raw boulders and rough blanking.

– Key trick: the blade must be luted to the shaft with molten 紫膠 (zǐ jiāo, shellac) while spinning; off-center by >0.2 mm and the kerf snags. - 琴陀 (qíntuó) – “lute” blade

– Smaller, 20–60 mm Ø. Flexible enough for 2-D contouring and shallow relief.

– Think of it as the historic equivalent of a router bit. - 鉤陀 (gōutuó) – profiled edge wheel

– Cross-section can be trapezoidal, lenticular, or undercut to create negative spaces.

– Perfect for dragon-scale textures or the reverse cuts on an open-work 璧 (bì) disc. - 軋陀 (yàtuó) – finishing burr

– Slightly thicker, blunt edge; flattens saw marks and pre-polishes grooves.

2.Drilling & Core-Removal

Two regimes exist: solid drills for <3 mm holes and hollow trepanning tubes for larger bores.

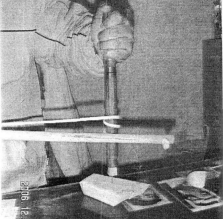

- 實心鑽 (shíxīn zuàn)

– Bronze, iron, or bamboo shafts tipped with quartz sand slurry.

– Bow-drill action: 30–40 rpm, 0.1 mm feed per stroke—slow but fracture-free. - 空心管鑽 (kōngxīn guǎn zuàn)

– Copper or iron tube with 0.5–1 mm wall, slit longitudinally to admit abrasive slurry.

– Used to “core” the interior of incense burners or bracelet blanks; the extracted cylinder becomes a bead pre-form, a textbook example of zero-waste thinking.

3.Polishing Arsenal – From 膠碾 to 蠟盤

Once the form is complete, surface refinement proceeds through progressively softer laps charged with 剛玉粉 (gāngyù fěn, corundum powder).

- 膠碾 (jiāo niǎn) – shellac-bonded disc

– Compliant matrix allows micro-conformity to complex reliefs; still preferred for nephrite cabochons. - 木輪 (mùlún) – wax-impregnated hardwood

– 600–1200 rpm with oil-borne rouge for flat facets; watch the grain direction or you’ll raise splinters. - 皮輪 (pílún) & 氈輪 (zhānlún) – leather and felt

– Leather for crisp edges, felt for soft curves. The artisan’s mantra: “硬皮軟氈, 亮而不傷” (hard leather soft felt, bright without bruise). - 蠟拋光盤 (là pāoguāng pán) – aluminium/ beeswax composite

– Final mirror finish on jadeite; micro-grooves hold 0.5 µm cerium oxide for optical-grade gloss.

- Hidden Physics – Why These Tools Work

Hardness differential: iron (4–5) vs nephrite (6.5) seems counter-intuitive, but the grit (quartz 7 or corundum 9) actually does the cutting. The wheel is merely the grit carrier. By controlling RPM (<100 for hand lathes) and slurry viscosity, ancient artisans achieved material-removal rates within 5 % of modern diamond wheels—yet with far less sub-surface damage. - Take-Home Challenge

Replicate a 琴陀 cut on a scrap of serpentine using a hobby drill and 600-grit SiC paste. Measure kerf width and compare to the 0.4 mm historical mean. Post your results in the Virtucasa forum; the closest match wins a museum-grade nephrite off-cut.

Conclusion

Understanding these tools(jade carving toolkit) is more than antiquarian curiosity. Every 陀, 鑽, and 碾 encodes centuries of empirical tribology—knowledge that still informs sustainable, low-impact lapidary today. Read the full series to watch slow-motion videos of a 300-year-old 鋸陀 slicing Hetian jade, and download CAD files to 3-D print your own historically accurate spindles.

Read more

- Collectors' Academy (178)

- Care Academy (8)

- Investment Academy (25)

- Jade Crafting Techniques (28)

- Michelle Au: The Gemstone Luminary (11)

- The Precious Metals & Jewels Compendium (55)

Natural Honey – Yellow Ice – Type Jadeite Bracelet

- USD: $2,560.00